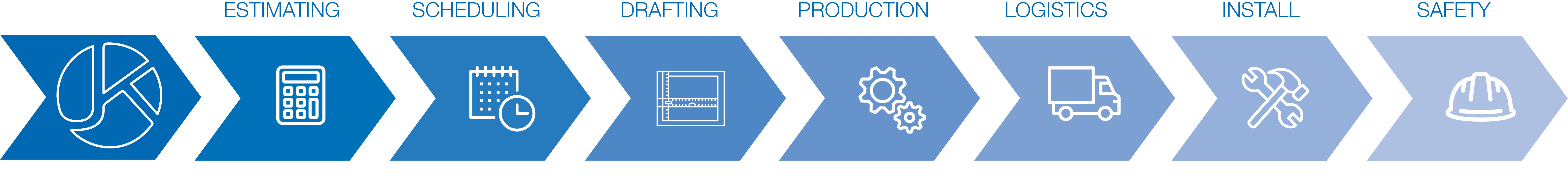

ESTIMATING

- Sourcing tenders based on architects plans and risk management checks, we go through the whole project and determine the scope of works involved

- We carefully dissect each aspect of the job and work closely with our suppliers to secure the best possible pricing to submit to the client/builder

SCHEDULING

- After successfully securing a project, we break down the job into dates required based on the construction programme provided and work back from there, we do this to ensure that the builder’s deadlines are met – we place the up-most importance on this

- The appropriate safety documentation & processes are then put into place for works to be completed on site

DRAFTING

- We use the latest Planit Cabinet Vision Software to achieve the most precise and detailed shop drawings and then arrange an exclusive prototype viewing at our Head Office

- This allows the Client, Builder & Architect to physically see their design and make any amendments to get the best possible outcome for the overall project.

PRODUCTION

- The approved apartment is downloaded into our CNC software and the CNC machines will then optimize and cut the project

- It is then moved to our edge bander machines where each individual panel is edged and ready to be assembled

- The production team will then manufacture the products in three separate divisions and stages depending on scope of works, then they will store in the holding bays where the appointed Manager will QC the works

LOGISTICS

- Once QC has been approved, a detailed report is sent to our site team to notify them of expected delivery

- Logistics staff will individually wrap each apartment component with protection to avoid any transport damages and stack onto large pallets which are wrapped securely

- Items are transported on-site where the Jamel team are ready to unload by forklift and begin the install process from cranes or lifts

INSTALL

- We engage one or two site supervisors depending on the size of project with full inductions and a Jamel site office.

- We will only use Professional site installers to begin the 4 stage process. This consists of 1st installation, 2nd Fix, 3rd Snag lists then 4th quality control for defects / Final PC.

- The factory has a 24 hour send to site policy for components or re-cuts making sure the Site Staff can perform to their optimum level

SAFETY

- Working both on and off-site, we are committed to delivering great service in a manner which ensures the health & safety of our employees, contractors, clients and members of the public

- We are dedicated to the continual improvement of our OHS management systems to enhance our performance